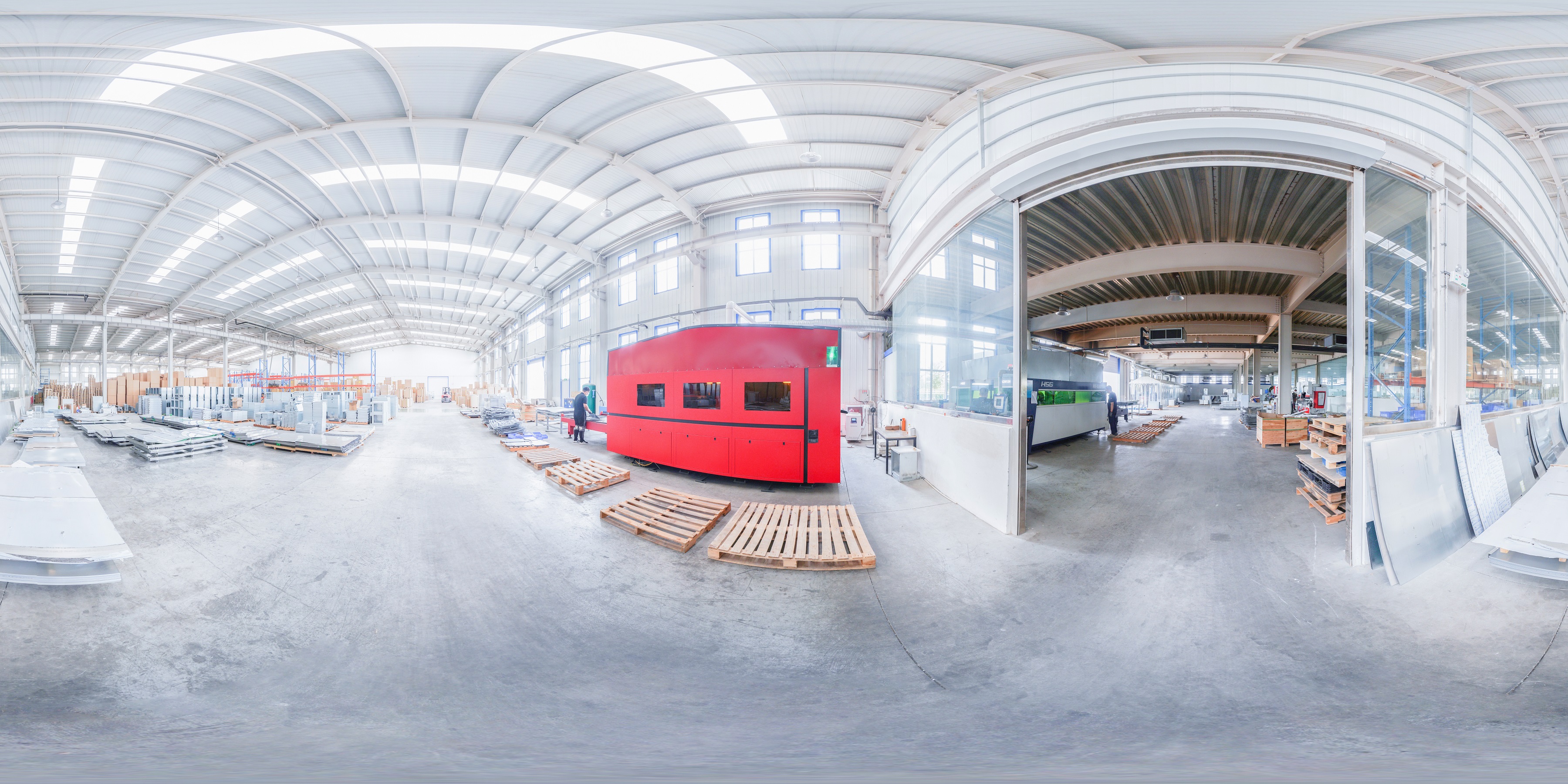

If we compare the industrial economy to a dragon, the instrument industry is the eye of the dragon, "said Mao Lei, Vice Chairman of the China Instrument Industry Association. As an important component of China's manufacturing industry, the instrumentation industry has played an important role in promoting the development of the national economy. After years of development, China's instrument and meter industry has reached a considerable industrial scale and entered a major country in instrument and meter production.

According to relevant data, the operating revenue of China's instrument manufacturing industry reached 766.00 billion yuan in 2020. In the first half of 2021, the operating revenue of China's instrument manufacturing industry reached 399.65 billion yuan, a year-on-year increase of 25.7%. Industry profits are gradually rebounding, and demand is further expanding.

In addition, due to the seven major areas of new infrastructure including 5G infrastructure, ultra-high voltage, intercity high-speed railway and intercity rail transit, new energy vehicle charging stations, big data centers, artificial intelligence, industrial internet, etc., it involves multiple key social and livelihood industries. The development of these seven major fields and multiple industries requires the manufacturing of instruments and related hardware. For the instrument industry closely related to the macro-economy and fixed assets investment, it will inevitably bring new opportunities to enterprises.

However, on the other hand, with the rapid progress of the industry, with the transformation of the economy and the continuous transfer of the world's manufacturing industry, many urgent problems in the instrument and meter industry have gradually emerged. Some problems, such as chaotic procurement management, uneven supplier supply quality, and weak innovation ability, still constrain the sustainable development of China's instrument and meter industry.

How can China's instrument and meter industry become larger and stronger as it enters a stage of high-quality development? How can digital transformation bring better development? We also need to play the role of these "four brushes".

01 Build a supplier management system and optimize the enterprise supply network

For domestic instrument and meter enterprises, maintaining close cooperation with suppliers has become their main mode of obtaining resources and delivering products and services on the supply chain.

At present, many instrument and meter enterprises are using ERP systems to manage suppliers. However, most ERP systems on the market only have supplier management and procurement functions, mainly for inventory and accounting purposes, to record supplier information and purchase orders, which cannot meet the needs of enterprise supplier management.

Modern SRM systems, such as the Digital Cloud SRM Supplier Management System, start from the enterprise's procurement strategy, support supplier performance evaluation, and promote increased competition through elimination or project-based procurement.

Building a professional SRM supplier management system, exploring, reviewing, and quantifying the relationship between buyers and suppliers through SRM, and regularly exchanging and communicating information on plans, work plans, and quality control with suppliers to maintain consistency and accuracy of information, is conducive to integrating the business processes of both suppliers and buyers, improving cooperation efficiency, controlling production in advance, sharing inventory and demand information, and jointly resisting market changes.

In addition, establishing long-term and close business relationships with suppliers can also help integrate resources and competitive advantages of both parties to jointly explore the market,